Hybrid Technology – Muscle Mustang And Fast Fords March 2006

| There are no electric motors assisting this 660hp Clevor stroker. |

| Courtesy of Muscle Mustangs and Fast Ford Magazine Article by Richard Holdener |

Hybrid technology is all around us, with both import and domestic manufacturers seeking ways to stretch fuel mileage without resorting wholly to pathetic electric vehicles. The new hybrid cars combine the efficiency of an electric motor and the convenience (and familiarity) of a conventional power train.

That’s great if you are a tree hugger, but the hybrid technology in this story has less to do with conserving fuel than it does how to maximize power production from the fuel that is still available. While our hybrid doesn’t combine regenerative braking with a hydrogen fuel cell, it does combine old and new technology in search of harmonious perfection.

Ask a guy who grew up during the muscle-car era about Ford hybrids, and likely as not you’ll wind up with the term Clevor. You see, late-model Mustang owners, while many of you can scarcely remember a time when we didn’t have umpteen intake manifolds and (more importantly) cylinder heads to choose from, Ford performance was alive and well long before the advent of 5.0.

Back in the 60’s Ford found a way to dramatically improve the performance potential of its 302/351 motors – enter the Cleveland engine. The new Clevelands had radically redesigned heads, included cavernous port volumes (especially in 4-V form), massive valve sizes, and altered valve angles. Never mind that the Cleveland heads bore a striking resemblance to those porcupine heads on the big-block Chevy, their flow potential (especially in modified form) far surpassed anything available for the Windsor. The fact that they performed so well in NASCAR, NHRA, and even Trans-Am racing helped sell the Cleveland as a high performance street motor. Though the flow was up considerably compared to a Windsor casting, the performance-orientated 4-V Cleveland heads proved a might too large for most street applications.

Rather than design a whole new small block family, the Ford engineers were smart (or frugal) enough to design Cleveland heads around the Windsor architecture. That meant the wild 351 Cleveland heads could be mated to the entire family of Windsor motors.

The 69 Boss 302 was actually the first (factory) Clevor hybrid, as the Boss heads were designed with the Windsor water passages. This hybrid technology was pretty popular back in the day and continues to find flavor amongst Cleveland fans, due mostly to the dwindling supply of useable Cleveland blocks. Since Ford continued to produce 351Windsor blocks for the next 30 or so years, they are in much greater supply. A Clevor build up using a cheap (available from the wrecking yard) factory Windsor block is a much more affordable alternative to stepping up to a pricey aftermarket Cleveland block.

While combining the Windsor with the nearly ancient Cleveland is enough of the something old and something new, oddly enough, the new portion of the equation actually comes from the Cleveland side.

Cylinder Head Innovations (CHI) offers a set of aluminum performance Cleveland heads. While Cleveland owners should rejoice in the availability of head gear lighter than the boat anchor of the Queen Mary, there is more to the package then the lost of tonnage. Not only did the boys at Cylinder Head Innovations decide that Cleveland enthusiasts deserve the weight savings so long enjoyed by the Windsor crowd, but they also saw fit to improve the inherent shortcomings of the original design. The altered valve angles offered by the Cleveland definitely help in power production, but the huge port volumes and valve sizes were improved to maximize flow while minimizing the all important cross section.

Big ports may flow well (most actually don’t), but they do not promote air speed ( that provides power producing cylinder filling) at low (and medium) engine speeds and partial throttle openings. If the production 4V Cleveland heads flowed 450cfm, then no one would complain about the Big Block sized port volume. That they flow 200cfm less than that number creates a problem. The experts at CHI recognize this fact and produced port dimensions and shapes that greatly improved the flow whilst simultaneously reducing the cross section (compared to a stock 4V). Any time you increase flow and decrease cross section, you now you’ve done something right.

Ford produced two varieties of the Cleveland heads, a 2V and a 4V. The designation was used not to describe the number of valves (as is now common for the 4.6 Modular motor), but rather the form of carburetion. The 2V heads featured smaller ports and were used in conjunction with a two barrel intake manifold and matching carburetor. As the designation implies, The larger 4V versions were used on high output applications equipped with the 4 barrel intake and carb.

It has long been thought that the ideal Cleveland cylinder head combination would offer the port size of the smaller 2V with the head flow of the 4V. This is exactly what the 3V head from CHI was designed to do, only more so. Like the factory offerings CHI offers its head in two configurations, but in this case the distinction is in the port volume.

The smaller 185cc heads were originally designed from heads run in the Engine Masters Challenge in 2002. The CHI headed small block Ford managed a second place finish, but the larger 218cc castings (like ours) were used by none other than Jon Kaase to win the 04 Engine Masters Contest. His Cleveland based small block Ford bested all other competitors (including this author, with conventional Windsor heads) to take his second win in a row (the 03 contest used Big Blocks).

Obviously, the same set of cylinder heads will not be ideal for all small block Ford combinations. This is why most manufacturers (AFR, Edelbrock, and TFS to name a few) offer different heads to meet the needs of engine builders. A stock 302 buildup will likely require a different head than a all-out race stroker. The gang at CHI recognized this, and now offers both the 185 and 218cc heads, along with the CNC ported versions.

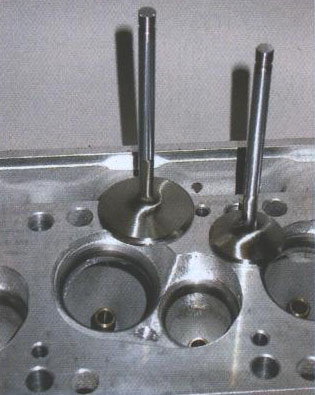

For the 408 stroker build up, we chose a set of out of the box 218ccheads. The 218 designation refers to the port volume. In addition to cutting the weight of the heads by more than half (compared to factory iron Cleveland heads), the CHI aluminum heads also featured a 2.150″ / 1.650″ valve combination, a 5/8″ deck thickness ( to minimize distortion), and high nickel chrome valve seat inserts.

For the 408 stroker build up, we chose a set of out of the box 218cc heads. The 218 designation refers to the port volume. In addition to cutting the weight of the heads by more than half (compared to factory iron Cleveland heads), the CHI aluminum heads also featured a 2.150″ / 1.650″ valve combination, a 5/8″ deck thickness ( to minimize distortion), and high nickel chrome valve seat inserts.

Despite the decreased cross section of the inlet port, the CHI heads can be used with the factory 2V and 4V intake manifolding, allowing for a more economical upgrade from the factory cast iron heads. Though our heads were shipped bare with valves, the heads are also available with a variety of different competition packages that provide the necessary valve springs, retainers, and associated hardware. According to CHI testing, the 218 heads offer 332cfm on the intake (at 0.700″ lift) and 225cfm on the exhaust. The intake flow exceeds 300cfm at 0.500″ lift, while the exhaust flow exceeds 200cfm at the same lift.

Though both 351 Cleveland and 351 Windsors share a common displacement, the deck height of the blocks differ between the two engine families. The Cleveland blocks sport a 9.2″ deck height, while the Windsor is slightly taller at 9.5″. While the deck height has no bearing on the head fitment, it does affect the intake manifold. The taller Windsor block requires a dedicated intake manifold. Luckily for Clevor hybrid enthusiasts, not only does CHI offer new aluminum Cleveland heads, but it also saw fit to step up and produce matching intake manifolds for both deck heights.

Knowing it heads would be utilized on both Cleveland and Windsor blocks, CHI whipped up performance single plane manifolds for both engines. In fact the company also decided to offer the manifolds with Dominator carb flanges, allowing enthusiasts to choose from some serious induction hardware. Like the cylinder heads, the CHI single plane intake was run on Jon Kaase”s winning EMC motor in 2004. Though the contest was run from 2500 – 6500 rpm is a testament to the companies concern not only for peak numbers, but also for the all important average power that wins both engine building competitions and races alike. For you Boss 302 fans, CHI also offers intake manifolds for the smaller 8.2″ deck Windsor blocks.

Rather than build an all out race motor, we decided to construct a healthy street – strip combination to properly test the merits of peak power potential as well as mid range torque production. To that end, we called on the stroker experts at Coast High Performance to assemble a Cleveland-friendly short block. The 408 stroker featured a 4″ stroker crank, a set of forged connecting rods, and forged flat top pistons with the proper valve reliefs for the canted-valve CHI ( Cleveland ) heads.

The block was topped with the CHI heads, matching single plane intake, and an 850 Barry Grant Mighty Demon carburetor. We installed one of our EMC test (roller) cams that offered a 0.672 / 0.688 lift split, a 246 / 249 duration split, and a 109 degree lobe separation angle. Also employed on the hybrid was a set of 1.73 roller rockers, a set of 1 7/8 inch Hooker ( Torino chassis) headers, and an MSD ignition. A Milodon oil pan assembly, a CSI water pump, a TCI Rattler balancer were also used in the buildup.

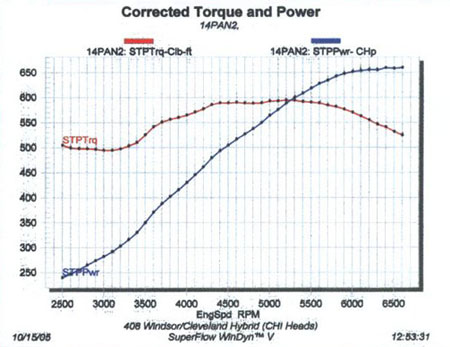

The 408 hybrid stroker was installed on the engine dyno and allowed to break in for 25 minutes before we changed the oil over to Lucas synthetic. It was then run in anger and tuned to perfection using the MSD billet distributor and jetting/air bleeds in the Mighty Demon carb. After only a handful of tuning runs, the Clevor thumped out an impression 660 hp at 6600 rpm and 595 lb-ft of torque at 5200 rpm on (91 octane) pump gas. The torque curve produced by the hybrid stroker was impressive, exceeding 550 lb-ft from 3.7 rpm to 6.3 rpm. Even way down at 2500 rpm, the stroker thumped out over 500 lb-ft of torque. Obviously, the CHI heads and intake combination were doing their job, allowing the 408 Clevor to not only produce exceptional peak power but also (and more importantly) one heck of a potent torque curve.

This is where the fun begins. Resin impregnated sand is poured into the mould. The resin bonds the sand together to form a very-soft sandstone-like consistency. In the more intricate areas, the sand is actually packed or compressed into all the small cavities by hand using prodders and other things. This is where the fun begins. Resin impregnated sand is poured into the mould. The resin bonds the sand together to form a very-soft sandstone-like consistency. In the more intricate areas, the sand is actually packed or compressed into all the small cavities by hand using prodders and other things. |

The CHI aluminum 3V Cleveland heads offered a huge weight savings over factory 4V or 2V iron castings. The aluminum heads weighed less than half of their iron counterparts. The CHI aluminum 3V Cleveland heads offered a huge weight savings over factory 4V or 2V iron castings. The aluminum heads weighed less than half of their iron counterparts. |

CHI 3V heads were equipped with a set of Manley stainless steel valves. The intake valves measured 2.1500 inches, while exhaust valves checked in at 1.650 inches. CHI 3V heads were equipped with a set of Manley stainless steel valves. The intake valves measured 2.1500 inches, while exhaust valves checked in at 1.650 inches. |

We equipped the CHI heads with a set of dual valve springs from the Comp Cams catalog. The spring package offered 240 pounds of seat pressure and 470 pounds of open pressure to work with our solid roller cam. We equipped the CHI heads with a set of dual valve springs from the Comp Cams catalog. The spring package offered 240 pounds of seat pressure and 470 pounds of open pressure to work with our solid roller cam. |

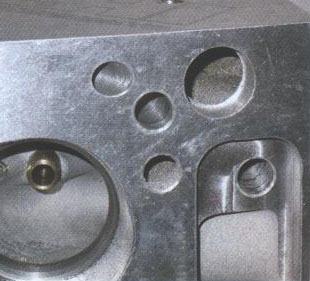

This shot illustrates the difference in port dimensions between the CHI intake and a conventional 4V manifold. Note the dramatic mismatch between the 4V gasket and the CHI intake port. This shot illustrates the difference in port dimensions between the CHI intake and a conventional 4V manifold. Note the dramatic mismatch between the 4V gasket and the CHI intake port. |

When running the 3V heads on a Windsor , two holes in the front of the CHI heads are used for external coolant passages. It is also possible to drill holes in the intake mating surface. When running the 3V heads on a Windsor , two holes in the front of the CHI heads are used for external coolant passages. It is also possible to drill holes in the intake mating surface. |

To maximize the performance of its 3V heads, CHI supplied one of its new Engine Masters Series intake manifolds. Since neither the 2V nor the 4V intake would mate perfectly to the 3V intake port, CHI saw fit to design a series of intakes to work with its new cylinder head. The single plane design obviously optimized midrange and top end power, but the stroker thumped out some impressive low speed torque as well. To maximize the performance of its 3V heads, CHI supplied one of its new Engine Masters Series intake manifolds. Since neither the 2V nor the 4V intake would mate perfectly to the 3V intake port, CHI saw fit to design a series of intakes to work with its new cylinder head. The single plane design obviously optimized midrange and top end power, but the stroker thumped out some impressive low speed torque as well. |

To properly test the merits of the CHI heads and intake, we called on Coast High Performance to build a 408 stroker short-block. The 315W block was stuffed with a 4.0 inch stroker crank and forged connecting rods. To properly test the merits of the CHI heads and intake, we called on Coast High Performance to build a 408 stroker short-block. The 315W block was stuffed with a 4.0 inch stroker crank and forged connecting rods. |

The forged flat top pistons offered the proper valve reliefs to work with the canted-valve Cleveland heads. The forged flat top pistons offered the proper valve reliefs to work with the canted-valve Cleveland heads. |

The solid roller cam from Comp Cams offered a 0.672/0.688 lift split to go along with the 246/249 duration split. Comp also supplied the necessary 838 solid roller lifters. The solid roller cam from Comp Cams offered a 0.672/0.688 lift split to go along with the 246/249 duration split. Comp also supplied the necessary 838 solid roller lifters. |

Since this was a Windsor based short block, we used an EMC oil pan supplied by Milodon. During testing, the Milodon pan showed some pretty impressive power gains by controlling the windage. Since this was a Windsor based short block, we used an EMC oil pan supplied by Milodon. During testing, the Milodon pan showed some pretty impressive power gains by controlling the windage. |

We installed a set of 1.73 roller rockers on the CHI heads. We installed a set of 1.73 roller rockers on the CHI heads. |

Barry Grant supplied an 850 Mighty Demon carb for use on our stroker. Barry Grant supplied an 850 Mighty Demon carb for use on our stroker. |

Given the potential power output of the stroker, we installed a set of Hooker 1 7/8 inch long tube headers. Given the potential power output of the stroker, we installed a set of Hooker 1 7/8 inch long tube headers. |

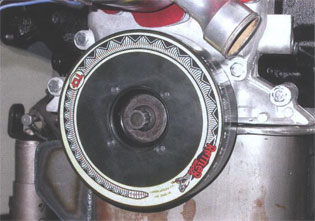

The 408 was balanced using a 28 ounce Rattler balancer from TCI. The 408 was balanced using a 28 ounce Rattler balancer from TCI. |

MSD supplied not only the billet distributor, but also the plug wires and Digital 7 ignition amplifier. MSD supplied not only the billet distributor, but also the plug wires and Digital 7 ignition amplifier. |

Once assembled on the dyno, the CHI-headed Clevor hybrid produced impressive power numbers. The 408 thumped out 660hp and 595 ft-lb of torque. Once assembled on the dyno, the CHI-headed Clevor hybrid produced impressive power numbers. The 408 thumped out 660hp and 595 ft-lb of torque. |

408 Windsor / Cleveland Hybrid 408 Windsor / Cleveland Hybrid |

Just check out the power produced by the CHI-headed 408 stroker. The combination of the 4-inch stroker crank, a healthy compression ratio, and the right cam profile made for one impressive powerplant. Top off the combination with a set of trick CHI 3V Cleveland cylinder heads and matching single-plane intake and you have the makings of one serious street engine. Despite the relatively high static – compression ratio, this motor produced 660hp and nearly 600 ft-lb of torque running on 91 – octane pump gas.