Our Results

Our Results

784.4hp 614.4 ft/lb from 3V 225cc heads and 4500 Dominator Manifold.

This monster of a motor was built by Phil Talmieri from Phil’s Automotive Service and Tune Shop (024 940 8402) in Newcastle NSW. Cylinder heads and manifold were massaged courtesy of Higgins Race Developments Victoria (Ph: 03 9768 3902).

The engine is based around a 9.2″ Dart block of 427ci in capacity. Camshaft is a custom Comp Roller. Engine was dyno tested at Baker Precision Engines on one of their own in house manufactured BAKER DYNOS, utilising Depac data acquisition (Ph: 02 6366 9225 )

| PRINT * 95 | A8414 | LOUIE.CFG | 426.FRC | Nov 2 ’05 | 11:53 AM # 1 |

| Baker Precision Engines (02) 6366-9225 | |||||

| |

|||||

| DEPAC # 283 | Fri Oct 28 ’05 | 4:43 PM | FT4-8 Flow | Tst* 8414 | 4000 to 7300 RPM |

| LOUIE.CFG | 408.INF | 29.92″ | Dry Air @ 60F | FUEL SG .704 | Time 10.3 |

| BARO:27.94 | Disp:427 | Bore:4.125 | p.jet:0 | s. jet:0 | oil .p:60 |

| Customer: LOUIE | Engine: 427 STROKER FORD | IGN Timing: 24 |

| Headers: | ||

| Carbs: BG 1095 METH ANNULAR | M.jet: |

Pwr valve: |

| Cam: COMP CAM ROLLER | Dur @ .050′: | Lobe lift: |

| A. jet: | Idle: | Emul tube: |

| Muffler: | Spacer: 1″ 4HOLE WILSON | Boost: |

| COMP: 13.2 | FUEL: METHANOL | |

| CRANKING COMP OLD GAUGE | PSI | |

3V Intake Manifold 220cc CHI Heads

| RPM | C TORQ | C PWR | A/ALKY | Fuel F A | Dens | VAC | OIL T | FUEL.P | RATE |

| BAND | Ft-Lbs | CHP | RATIO | #/Hr | 100 % | IN/HG | Deg F | PSI | RPM/S |

| 4045 | 522.0 | 402.0 | 5.26 | 89.0 | -9.4 | 11.9 | 3 | ||

| 4100 | 525.4 | 410.2 | 5.23 | 89.0 | -9.5 | 11.9 | 82 | ||

| 4200 | 532.4 | 425.8 | 5.26 | 89.0 | -9.5 | 11.9 | 236 | ||

| 4300* | 540.6 | 442.6 | 5.26 | 89.0 | -9.6 | 12.1 | 330* | ||

| 4400* | 548.7 | 459.7 | 5.26 | 89.0 | -9.6 | 12.1 | 388* | ||

| 4500* | 556.9 | 477.2 | 5.29 | 89.0 | -9.6 | 12.1 | 361* | ||

| 4600* | 565.4 | 495.2 | 5.36 | 89.0 | -9.6 | 12.1 | 341* | ||

| 4700* | 573.7 | 513.4 | 5.37 | 89.0 | -9.6 | 12.2 | 420* | ||

| 4800* | 581.7 | 531.6 | 5.39 | 89.0 | -9.6 | 12.5 | 432* | ||

| 4900* | 588.4 | 549.0 | 5.38 | 89.0 | -9.7 | 12.7 | 286* | ||

| 5000* | 592.4 | 564.0 | 5.35 | 89.0 | -9.7 | 12.9 | 356* | ||

| 5100* | 595.9 | 578.8 | 5.37 | 89.1 | -9.7 | 13.0 | 390* | ||

| 5200* | 600.4 | 594.5 | 5.43 | 89.1 | -9.7 | 13.1 | 400* | ||

| 5300* | 802.8 | 808.3 | 5.46 | 89.1 | -9.8 | 13.1 | 466* | ||

| 5400* | 601.9 | 618.9 | 5.48 | 89.1 | -9.8 | 13.1 | 544* | ||

| 5500* | 605.2 | 633.7 | 5.48 | 89.1 | -9.8 | 13.1 | 572* | ||

| 5600* | 605.8 | 645.9 | 5.51 | 89.1 | -9.8 | 13.1 | 642* | ||

| 5700 | 608.0 | 659.8 | 5.54 | 89.1 | -9.8 | 13.3 | 182 | ||

| 5800* | 608.2 | 671.7 | 5.59 | 89.1 | 9.9 | 13.4 | 686* | ||

| 5900* | 608.6 | 883.7 | 5.61 | 89.1 | -9.9 | 13.2 | 464* | ||

| 6000 | 614.0 | 701.4 | 5.63 | 89.1 | -9.9 | 13.5 | 138 | ||

| 6100* | 612.7 | 711.6 | 5.82 | 89.1 | -9.9 | 13.8 | 453* | ||

| 6200* | 613.5 | 724.2 | 5.60 | 89.1 | -10.0 | 14.0 | 636* | ||

| 6300* | 613.9 | 738.4 | 5.57 | 89.1 | -10.0 | 14.0 | 231* | ||

| 6400* | 613.2 | 747.2 | 5.59 | 89.1 | -10.0 | 14.0 | 518* | ||

| 6500* | 609.8 | 754.4 | 5.58 | 89.1 | -10.0 | 14.0 | 596* | ||

| 6600* | 607.2 | 763.0 | 5.54 | 89.1 | -10.1 | 14.0 | 468* | ||

| 6700* | 801.4 | 787.2 | 5.52 | 89.1 | -10.2 | 14.0 | 429* | ||

| 6800* | 594.8 | 770.1 | 5.50 | 89.1 | -10.2 | 14.2 | 591* | ||

| 6900* | 588.3 | 772.8 | 5.51 | 89.1 | -10.2 | 14.2 | 433* | ||

| 7000* | 582.8 | 776.7 | 5.50 | 89.1 | -10.1 | 14.3 | 533* | ||

| 7100* | 578.2 | 781.7 | 5.51 | 89.1 | -10.1 | 14.3 | 449* | ||

| 7200* | 570.9 | 782.7 | 5.53 | 89.1 | -10.1 | 14.3 | 509* | ||

| 7287* | 565.4 | 784.4 | 5.53 | 89.1 | -10.1 | 14.5 | 230* | ||

| AVRG | 591.55 | 638.68 | 5.469 | 89.07 | -9.84 | 13.24 | 432 | ||

AVERAGE RESULTS From 4200 RPM to 7100 RPM DEPAC * 283

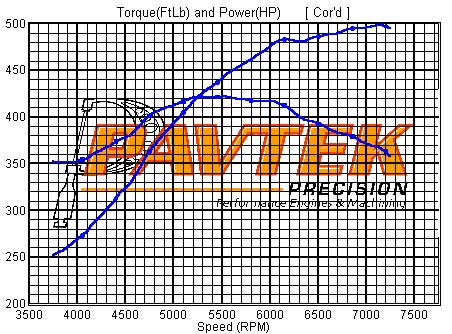

758hp and 580 ft/lb with 3V heads

3.Bill Kaglatzis C/O BK Engines. Ph:(0400 351 400) |

Here it is all 758hp and 580 ft/lb with 3V heads. Engine combo consists of : 400 cube, Dart block, Eagle 4340 crank, CP pistons with 14.6:1 comp, BK custom grind cam with .700 lift & 270@.050, Weiand tunnel ram converted to suit Enderlie bird catcher, Peterson wet-vac oil pump with belt driven dizzy & belt driven Enderlie 80a fuel pump.

BK Race Engines Page 1 of 1

Listing of (memory data)

Channel Group: Corrected Torque and Power Page 1 of 1

Printed on Ju1 8, 2005 at 15:07:41

Test Description: Accel. Test – 600 rpm/second

| Eng Spd | STPTrg | STPPwr | Fuel A | Fuel B | A/F | Air l | BSFC | VolEff |

| RPM | Clb-ft | Chp | lb/hr | lb/hr | Ratio | scrm | lb/hph | |

| 5500 | 581.7 | 609.1 | 0.0 | 0.0 | 0.00 | 0 | 0.000 | 0.0 |

| 5600 | 572.2 | 610.1 | 0.0 | 0.0 | 0.00 | 0 | 0.000 | 0.0 |

| 5700 | 569.5 | 618.1 | 0.0 | 0.0 | 0.00 | 0 | 0.000 | 0.0 |

| 5800 | 569.8 | 629.2 | 0.0 | 0.0 | 0.00 | 0 | 0.000 | 0.0 |

| 5900 | 568.1 | 638.1 | 0.0 | 0.0 | 0.00 | 0 | 0.000 | 0.0 |

| 6000 | 565.9 | 646.5 | 0.0 | 0.0 | 0.00 | 0 | 0.000 | 0.0 |

| 6100 | 562.7 | 653.5 | 0.0 | 0.0 | 0.00 | 0 | 0.000 | 0.0 |

| 6200 | 569.7 | 672.5 | 0.0 | 0.0 | 0.00 | 0 | 0.000 | 0.0 |

| 6300 | 563.5 | 675.9 | 0.0 | 0.0 | 0.00 | 0 | 0.000 | 0.0 |

| 6400 | 567.1 | 691.1 | 0.0 | 0.0 | 0.00 | 0 | 0.000 | 0.0 |

| 6500 | 565.7 | 700.1 | 0.0 | 0.0 | 0.00 | 0 | 0.000 | 0.0 |

| 6600 | 564.2 | 709.0 | 0.0 | 0.0 | 0.00 | 0 | 0.000 | 0.0 |

| 6700 | 565.6 | 721.5 | 0.0 | 0.0 | 0.00 | 0 | 0.000 | 0.0 |

| 6800 | 565.5 | 732.2 | 0.0 | 0.0 | 0.00 | 0 | 0.000 | 0.0 |

| 6900 | 550.8 | 723.7 | 0.0 | 0.0 | 0.00 | 0 | 0.000 | 0.0 |

| 7000 | 545.0 | 726.3 | 0.0 | 0.0 | 0.00 | 0 | 0.000 | 0.0 |

| 7100 | 544.8 | 736.5 | 0.0 | 0.0 | 0.00 | 0 | 0.000 | 0.0 |

| 7200 | 539.9 | 740.1 | 0.0 | 0.0 | 0.00 | 0 | 0.000 | 0.0 |

| 7300 | 538.4 | 748.3 | 0.0 | 0.0 | 0.00 | 0 | 0.000 | 0.0 |

| 7400 | 537.6 | 757.4 | 0.0 | 0.0 | 0.00 | 0 | 0.000 | 0.0 |

| 7500 | 526.6 | 751.9 | 0.0 | 0.0 | 0.00 | 0 | 0.000 | 0.0 |

“2004 Engine Masters Championship winning racing cylinder heads and manifolds” |

At CHI we don’t expect you the customer to just take our word on the performance potential of our cylinder heads and manifolds. Unlike most companies we believe our results truly speak for themselves.

At the 2002 Engine Masters Competition we placed runner up overall whilst posting the highest peak torque and horsepower numbers of the field. If that wasn’t enough we were the most powerful Small Block Ford Cylinder Head and manifold by a proverbial mile.

At the 2004 Engine Masters we were determined to prove decisively that our 2002 results were no accident.

With no fewer than 4 entries using our 3V 225cc Cleveland Cylinder Heads and manifolds we blitzed the field of 40 entrants. Of the 6 finalists we had the winning engine of Jon Kaase and the no 5 placed engine of Scott Main and Bob Moore from MPG Heads both utilizing our 3V Cylinder Heads. No other manufacturer had two of their cylinder heads in the top 6, nor could they lay claim to having been chosen as the only supplier of any make of cylinder head in the competition.

If the Engine Masters Competition was not enough proof of the quality and performance offered by our cylinder heads and manifolds take the time to read in the articles section our independent test performed by Muscle Mustangs and Fast Fords Magazine (Thunder from Down Under) in the US. Also coming Dec 2005- Jan 2006 Muscle Mustangs and Fast Fords tests our as cast heads and manifolds on a 408 W for some truly astounding results.

We along with our customers have also spent many hours testing and validating our own products and we have listed below just some of our results. If you would like more information on other builds feel free to contact us as we have an extensive library from our own dyno and our distributors as well.

CHI 2V vs. hand ported Cast iron 2Vs = 58 more hp and 20ft/lb more torque

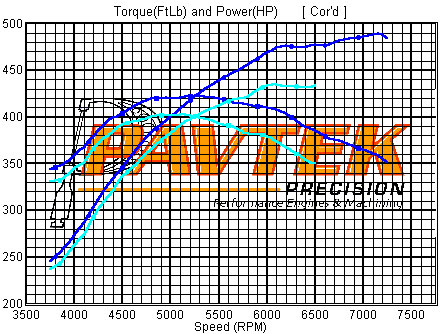

Pavtek Performance Engines and Machining in Epping Melbourne (Ph: 03 94087726) decided to test for themselves the new CHI 2V head against a pair of well ported cast iron 2V heads. The test was carried out on a standard stroke pump gas 10.5-1 compression 351 Cleveland with a +.030″ bore. The manifold was an Active 2V that had been well ported and the camshaft was a solid grind in the mid 240s @.050″on the intake with mid 250s @.050″ on the exhaust and valve lift was in the .550″ lift area. Headers were a pair of off the shelf Pacemaker 1 ¾” primary units. No other changes were made except for the swapping of the cylinder heads for the test. The graph with the 2 tests is the back to back running of the cast iron heads vs. alloys whilst the 2nd graph is the alloy headed engine with a set of 1 7/8″ primary headers.

The results were awe inspiring. The alloy units produced an amazing 58 more peak horsepower whilst raising the peak hp rpm a further 1000rpm, and also adding a further 20+ ft/b of torque. All from a simple cylinder head swap. Even more amazing was the addition of 1 7/8″ headers saw the engine nudging 500hp!!!

| Test id: *NEW 2V CHI heads – RR3 | ||||

| Customer: | Heads: | CHI 2V Heads | ||

| Test Date: | 4-Oct-2005, 18.10 | Camshaft: | Crane F248 | |

| Test N: | 2348 Operator : Theo | Manifolds: | Ported Active 2V+2″ Pavtek Spacer | |

| Regd No: | Induction: | Demon | ||

| Engine: | 351 Ford Clev- | Exhaust: | Dyno Pm 1344>1 | |

| Capacity: | 358.9ci | Compression: | 10.73:1 | |

| Correction: | 3.12 $AC JB07 | Cylinders: | 8(1-2-3-4-5-6-7-8) | |

| Fuel: | Synergy | |||

| Test id: 2V PortedCast iron Heads | ||||

| Customer: | Heads: | Ported 2V | ||

| Test Date: | 21-Mar-2005, 13.19 | Camshaft: | Crane F248 | |

| Test N: | 1784 Operator : Theo | Manifolds: | Ported Active 2V | |

| Regd No: | Induction: | Demon | ||

| Engine: | 351 Ford Clev- | Exhaust: | Dyno 1344>1 | |

| Capacity: | 358.9ci | Compression: | 10.99:1 | |

| Correction: | 4.12 $AC JB07 | Cylinders: | 8(1-2-3-4-5-6-7-8) | |

| Fuel: | Synergy | |||

CHI2V vs. 2V cast iron Graph |

| Test id: *CHI 2V Heads -1 7/8 pipes | ||||

| Customer: | Heads: | CHI 2V Heads | ||

| Test Date: | 4-Oct-2005, 18.50 | Camshaft: | Crane F248 | |

| Test N: | 2351 Operator : Theo | Manifolds: | Ported Active 2V+2″ Pavtek Spacer | |

| Regd No: | Induction: | Demon | ||

| Engine: | 351 Ford Clev- | Exhaust: | 178 Parameters | |

| Capacity: | 358.9ci | Compression: | 10.73:1 | |

| Correction: | 3.33 $AC JB07 | Cylinders: | 8(1-2-3-4-5-6-7-8) | |

| Fuel: | Synergy | |||

CHI2V500hp1 7/8 primary graph |

515 Hp 470 Ft/lbs Pump Gas Terror

In order to bring to you some real world dyno comparisons, we screwed together a near standard 351 Windsor, with the aim being to build an affordable engine that will run on standard pump fuel, with as few exotic parts as possible. We started out with a 351 Windsor block bored to .030″; and fitted with a KB 151 5/64 ring, hypereutectic piston package, giving us a streatable 9.9-1 compression ratio. The pistons were mated up to a standard, linished and tuftrided crank, using Eagle SIR I-Beam Standard replacement rods part no SIR 5956FP. In keeping with the not to exotic theme we decided to test a hydraulic cam as well as a similarly sized solid, to bring to you the best of both worlds.

The Hydraulic cam came in at 234@.050 on the Intake with 238@.050 on the Exhaust, 108 L/C and a .350 Lobe lift. The solid featured a 239@.050 Intake with 242@.050 on the Exhaust, 108 L/C and a .360 Lobe lift. The short motor had our out of the box EM185cc cylinder heads fitted as well as our Engine Masters Inlet Manifold. Controlling the Ferrea 2.08 Inlet valves and Manley custom 1.650″; exhaust valves were a set off Comp Cams Big Block Chevy 1.7-1 Chrome Molly roller rockers. Topping of the whole package was a Demon 830 mechanical secondary and a set of Hooker 1-3/4″; primary 31″ long headers.

The results speak for themselves!

| Dyno Test Results | ||||

| EM 185 234@.050 Hyd cam | EM 185 239 @ .050 Solid | |||

| RPM | HP | TQ | HP | TQ |

| 4600 | 410.8 | 469 | 406.3 | 463.9 |

| 4700 | 416.9 | 465.9 | 420.4 | 469.8 |

| 4800 | 422.5 | 462.3 | 432.3 | 473 |

| 4900 | 439.3 | 470.9 | 442.4 | 474.2 |

| 5000 | 447.9 | 470.5 | 449.6 | 472.3 |

| 5100 | 459 | 472.7 | 460.2 | 473.9 |

| 5200 | 467.1 | 471.8 | 465.1 | 469.8 |

| 5300 | 474.1 | 469.8 | 478.4 | 474.1 |

| 5400 | 484.8 | 471.5 | 489.2 | 475.8 |

| 5500 | 494.4 | 472.1 | 496.7 | 474.3 |

| 5600 | 496.7 | 465.8 | 502.5 | 471.3 |

| 5700 | 496.4 | 457.4 | 507.6 | 467.7 |

| 5800 | 500 | 452.8 | 513.6 | 465.1 |

| 5900 | 504.6 | 449.2 | 515 | 458.4 |

| 6000 | 506.5 | 443.4 | 516.5 | 452.1 |

| 6100 | 510.2 | 439.3 | 518 | 446 |

| 6200 | 516.9 | 437.9 | 522.8 | 442.9 |

| 6300 | 514.6 | 429 | 519.5 | 433.1 |

| 6400 | 516.6 | 423.9 | 523.4 | 429.5 |

| 6500 | 512.4 | 414 | 518.8 | 419.2 |

| 6600 | 513.7 | 408 | 516.9 | 411.3 |

| AVG | 505.27 | 453 | 510.7 | 457.9 |

Testing the EM 185cc cylinder head

After our success at the 2002 Engine Masters Challenge, we set about developing the all new Engine Masters (EM)185cc cylinder head. Our objective was to offer to the public an out of the box cylinder head with all the benefits of Dave Storlien’s hand ported castings. Our expertise in cylinder head design and manufacture led to us developing a cylinder head with almost identical flow characteristics to the hand ported version. This was achieved partially through the careful and extensive testing of valve seat cutter combinations.

Flow figures, are however only one part of a much larger equation, and in order to verify the performance potential of the new out of the box castings, we decided to test them against the very cylinder heads they were based on. The out of the box EM185 castings were bolted on to Dave Storlien’s 366 Clevor from the Engine Masters Challenge, and run down to Applied Dyno Technology MN for a full evaluation. All testing was performed through mufflers and with an air filter mounted.

| Dyno Test Results | ||||

| EM 185 hand finished head | EM 185 As cast | |||

| RPM | HP | TQ | HP | TQ |

| 4600 | ||||

| 4700 | 472 | 528 | 455 | 508 |

| 4800 | 475 | 519 | 474 | 519 |

| 4900 | 482 | 516 | 478 | 513 |

| 5000 | 487 | 511 | 490 | 515 |

| 5100 | 498 | 513 | 497 | 512 |

| 5200 | 510 | 516 | 502 | 507 |

| 5300 | 518 | 513 | 511 | 506 |

| 5400 | 519 | 505 | 522 | 507 |

| 5500 | 532 | 508 | 521 | 497 |

| 5600 | 534 | 501 | 525 | 492 |

| 5700 | 547 | 504 | 529 | 488 |

| 5800 | 553 | 500 | 538 | 487 |

| 5900 | 556 | 495 | 538 | 479 |

| 6000 | 561 | 491 | 545 | 477 |

| 6100 | 561 | 483 | 552 | 475 |

| 6200 | 567 | 480 | 555 | 470 |

| 6300 | 571 | 476 | 558 | 465 |

| 6400 | 574 | 471 | 562 | 461 |

| 6500 | 581 | 469 | 562 | 454 |

| 6600 | 580 | 461 | 568 | 447 |

| AVG | 562 | 524.2 | 551.6 | 488.9 |

3V185cc V 3V218cc title fight on 408W.

To answer some of our customer’s questions, as well as a few of our own, we decided to piece together a recognizable engine package, in order to, back to back test, our Engine Masters 185 cylinder head against our new 3V 225cc inlet port. We started out with a junkyard 351W block, bored and honed it to suit custom Manley forged pistons – 1.125 pin height, 1/16 – 1/16 – 3/16 ring package and a 15cc chamber shaped dish, netting us a healthy 11.0-1 compression ratio. These were attached to a Eagle 4340 crankshaft with 3.945 stroke via a set of custom Manley 6.400″ rods.

The camshaft used was a custom Elgin Cams grind with the following specs. Inlet lobe 249 @ .050, Ex 251 @ .050 with valve lift figures of .562″ and .581″ respectively. The job of actuating the valves was given to a set of Comp Cams, Chrome Molly, 1.7 – 1 ratio, Big Block Chevy rockers. Comp also got the nod for valve springs where a set of #950 springs were called upon for valve control duties, with the help of some Titanium retainers.

The aim of the test was to compare the two cylinder heads as well as our new prototype inlet manifolds, for both the EM 185 and the 3V 225cc cylinder heads. Both manifolds were tested with a Demon 820 Annular Discharge Carby with removable venturi’s, running on high octane pump fuel. Headers were a set 4bbl Hooker items, with 30″ long, 1 &Mac178;” primaries. In order to evaluate the two port designs accurately, both heads had their valve seats machined to the same size, i.e. 2.080″ Inlet and 1.650″ exhaust valves, and were used as supplied to customers, straight out of the box.

All testing was performed on Applied Dyno, MN, Superflow 901 dynamometer.

| Dyno Test Results | ||||

| EM 185 | 3V 225cc | |||

| RPM | HP | TQ | HP | TQ |

| 3100 | 284 | 481 | 275 | 465 |

| 3200 | 298 | 489 | 288 | 472 |

| 3300 | 309 | 492 | 294 | 468 |

| 3400 | 317 | 489 | 302 | 467 |

| 3500 | 321 | 482 | 313 | 469 |

| 3600 | 327 | 477 | 319 | 465 |

| 3700 | 335 | 476 | 326 | 462 |

| 3800 | 350 | 483 | 333 | 461 |

| 3900 | 360 | 485 | 348 | 469 |

| 4000 | 383 | 489 | 373 | 489 |

| 4100 | 395 | 505 | 390 | 500 |

| 4200 | 412 | 515 | 416 | 520 |

| 4300 | 437 | 533 | 436 | 533 |

| 4400 | 451 | 539 | 456 | 544 |

| 4500 | 465 | 542 | 469 | 547 |

| 4600 | 476 | 544 | 480 | 548 |

| 4700 | 488 | 546 | 491 | 549 |

| 4800 | 501 | 548 | 505 | 552 |

| 4900 | 514 | 551 | 518 | 555 |

| 5000 | 527 | 553 | 519 | 545 |

| 5100 | 531 | 547 | 526 | 542 |

| 5200 | 536 | 541 | 533 | 539 |

| 5300 | 535 | 530 | 534 | 529 |

| 5400 | 530 | 515 | 539 | 524 |

| 5500 | 532 | 508 | 539 | 515 |

| 5600 | 534 | 500 | 546 | 512 |

| 5700 | 531 | 498 | 556 | 512 |

| 5800 | 536 | 485 | 575 | 521 |

| 5900 | 543 | 484 | 584 | 519 |

| 6000 | 547 | 479 | 586 | 510 |

| 6100 | 553 | 476 | 587 | 499 |

| 6200 | 548 | 464 | 587 | 490 |

| 6300 | 543 | 453 | 589 | 475 |

| 6400 | 547 | 449 | 591 | 472 |

| 6500 | 537 | 434 | 588 | 472 |

| AVG | 458.1 | 502.3 | 466.0 | 506.0 |

|

|

Please click here to watch the video

Please click here to watch the video

To complete and verify our dyno testing results, the Dave Storlien built 366 Clevor pump gas engine from the 2002 Engine Masters Challenge was slotted into Richard Browns Fox chassis mustang and towed down to Cedar Falls Raceway for some track testing and evaluation.

The motor was run in full Engine Masters trim including air cleaner and full exhaust system. One pass was all that was needed to produce this number, and although the 60ft time was well down due to excessive wheel spin at the start line, unfortunately the weather closed in, and the guys were not able to make the necessary adjustments, to get the car down the track in a time more representative of its true potential, based on its terminal speed.

A quick look at the drag racers bible, the Moroso Power – Speed calculator, tells us that the car, will on a good pass have run in the 10.2 sec range and is producing approximately 540 hp in the car.

The incremental et and mph figures were as follows:

| Incremental et | MPH |

| 60 ft | 1.639 |

| 30 ft | 4.492 |

| 1/8 mile | 6.318 |

| 1000 ft | 5.974 |

| p mile | 10.632 |

| MPH | 130.80 |

Unfortunately the 1/8 MPH beams were not functioning in the right lane so these figures were not available for us to post.

|

|

Chassis, Rear Housing Fabricating, Roll Cage, and Tubing. |

|

History of Richard Brown’s 82 Ford Mustang

It started in 1996 when Richard purchased this 82 GT Mustang with a .030 over 302 with 9 to 1 compression performer RPM cylinder heads, cam shaft, intake and a Holley 650 double pumper. The car had a C-4 with a 2400 stall converter and a reverse manual valve body; also a stock 7.5 rear-end with 2.79 gears. Interior was stock 82 GT with American Racing 14 inch wheels on it.

It wasn’t stock for long, during the summer of 97 I put in a 12 point roll cage, 9 inch rear-end with 430 gears, south side lift bars, and a cheap NOS cheater kit. After making a couple of trips to the race track that Fall Richard got the car to run 10.80 at 124mph, with a 175 shot of NOS. Over the next two Winters Richard mini-tubbed it, put in a ladder bar , coil over rear suspension, stretched the quarters for 31 inch tall tires, put on 90lx bumpers and quarter windows. Next they updated the motor by ordering a Probe Industries 408 stroker short-block, then ported the performer RPM cylinder heads, installed 2055 intake valves and topped it off with a Super Victor intake and a 750 carburettor; the transmission was then changed to a power glide with a 5000 stall converter and trans brake. After those modifications it ran 10.50 on the motor and 9.98 on a 150 hp of NOS.

Four years later it now has Victor Jr. cylinder heads, 850 Holley, and a 300 hp of NOS, has ran 9.33 at 142mph on 31×16.5ET Streets and through the mufflers.

At the 2002 World Ford Challenge, Richard qualified #12 out of 49 cars in the wild street class.